uses and applications

Cooling Towers

Cooling towers offer a proven cost-effective solution.

The main use of cooling towers is to lower the temperature of the water used.

One of its main advantages is that they do not use compressors, which considerably lowers the cost of the equipment, as well as the cost of electricity.

During operation, condensed or process water flows directly over the heat transfer surfaces of the cooling tower. As air enters the tower, some of that water evaporates, cooling the remaining water.

When the desired temperature is medium-high, a cooling tower is ideal.

This equipment is used to lower the temperature of water. Some of the main industries where they are used are: Plastics, automotive, food, beverage, power generation and HVAC industries, among other applications.

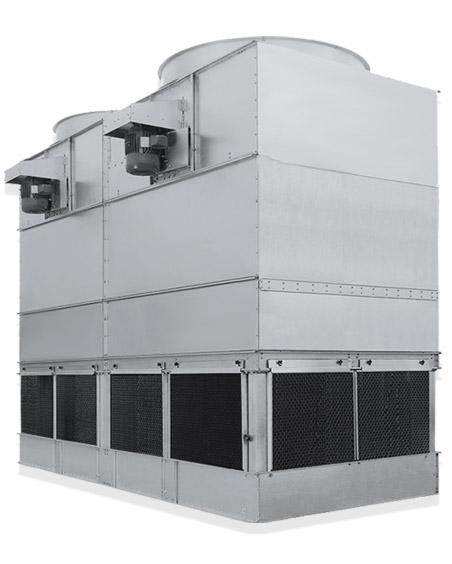

COOLING TOWERS

By Direct Evaporation

Manufactured with high resistance and quality materials:

- Galvanized Steel

- Stainless Steel

- Fiberglass reinforced with galvanized steel

- Fiberglass reinforced with stainless steel in its basic structure, which provides resistance and durability to mechanical work as well as resistance to corrosion and degradation by UV rays due to the special formulation of the resins used.

COOLING TOWERS

Indirect Evaporation

Cooling towers are used to cool water in large volumes, extracting heat from the water by means of a heat transfer mechanism known as evaporation, which is a physical process where a small part of the water passes from the physical state to a gaseous state and in this way the steam and air acquire the energy in the form of heat contained in the water.

To avoid corrosion in cooling towers it is recommended to:

- Install corrosion cores

- MPY corrosion rate monitoring

- Equipment and piping protection

To avoid fouling it is recommended to follow the following points:

- Equipment and piping protection

- Process optimization

- Maintain heat transfer efficiency

- Avoid costly corrective maintenance

By avoiding fouling, you will have:

- Control of microbiological proliferation

- Elimination of algae, fungi and yeasts

- Decrease of unscheduled maintenance shutdowns

COOLING TOWERS

Fiberglass

At Ecochillers we use first quality materials, such is the case of Reichhold Polylite resins in the manufacture of our towers, so we can assure durability for more than 20 years.

The towers have a metallic structure (galvanized steel or stainless steel) that allows it to support the mechanical work avoiding collapse as it happens with some 100% fiberglass towers existing in the market.

FRP formulation that prevents fiberglass degradation by UV rays.

COOLING TOWERS

Stainless Steel

We know that there is a great variety of processes in the industry, therefore an option for the food industry or where the use of sanitary equipment is required is the implementation of stainless steel towers (both in closed or open circuit).

An excellent alternative is Ecochillers' stainless steel or galvanized steel towers, since they are manufactured in high quality stainless steel and chemical or sanitary processes that require it.

All major components of the cooling towers have protection on the motors, axial fans, fan assembly and unit, which have been developed to ensure maximum efficiency with low energy consumption.