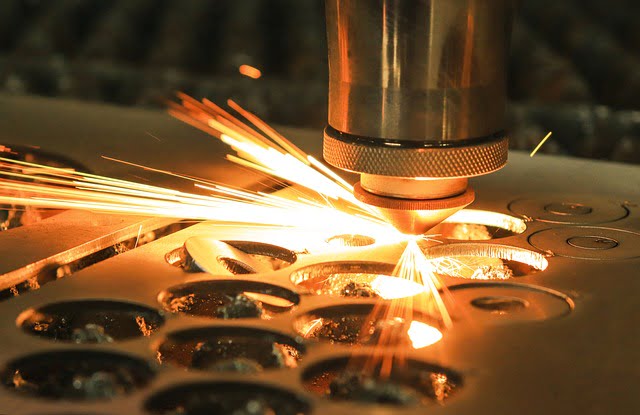

Metal Mechanical Industry

Chillers for

mechanical metal cutting.

Application of Chillers:

- Laser Chiller

- Chiller chillers are used to cool the lasers and the power supplies used to power them.

Chiller for Printing or Rotary Printing

Chiller chillers are used to remove the heat generated by the printing rollers and also cool the paper after it comes out of the ink drying ovens.

EDM Chiller

Chiller chillers are used to keep the machinery at room temperature during the cutting process.

Chiller JET or laser waterjet cutting machinery

Chiller chillers are used to cool the machine spindle as it produces the workpiece and cools the liquid that is sprayed known as Coolant.

Laser types:

- CO2 lasers.

- Nd:Yag.

- Diode / Solid State.

1.- Calculation of chiller for metal mechanic industry, laser, welding machines, pointing machines, necessary information:

- Laser Model.

- Resonator thermal load.

- Thermal load optics.

- Laser Flow rate.

- Pressure drop across the laser.

- Fluid outlet temperature.

- Stability Temperature Requirements.

- Water Quality Requirements.

- Linear motors.

In laser cooler

Chiller 1 to 5 tons

Laser installation tips:

- Chiller or Cooler to be of piping, connection and process must be of non-ferrous metal construction.

- Outdoor installations are glycol, other mixtures require special design.

- Take into account the cooling distance for the process.

- Piping above the chiller requires new anti-flow kit or check valves.

- The water must be clean and 100 microns or more.

- Bacterial inhibitors should be taken into account when citing since many inhibitors create problems with seals.

- Deionized water-qualities to over 200,000M-ohm resistance will require plastic or stainless steel.

- Stitchers.

- Wire welders.

- Water jet or jet cutters.

- Laser cutting machines.